IDEA OSG 1 (In-situ Debris Environmental Awareness / OSG 1 Project)

Non-EO

Space Situational Awareness

Quick facts

Overview

| Mission type | Non-EO |

| Launch date | 28 Nov 2017 |

| End of life date | 28 Nov 2017 |

IDEA OSG 1 (In-situ Debris Environmental Awareness / OSG 1 Project)

Spacecraft Launch Sensor Complement Ground Segment References

IDEA OSG 1 is a microsatellite of 22 kg that will measure small-size debris orbiting the Earth — this comprises debris the size of grains of sand (0.1 to several mm). Astroscale Pte. Ltd. of Singapore is developing the IDEA OSG 1 microsatellite, based on a concept born in the Hanada Laboratory at Kyushu University. Micro-debris has the potential to inflict lethal damage on satellites, and yet neither its distribution nor quantities are fully known, and as such, a better understanding of this debris, as well as tracking are required. The mission of "IDEA OSG 1" is to dynamically construct a micro-debris environmental model (a model defining the distribution and current quantities of debris) from micro-debris measurement data, and to use this in formulating measures to both counter debris in the design of spacecraft, and minimize collision damage. 1) 2) 3)

IDEA OSG 1 is the world's first microsatellite for the tracking and mapping of space debris. The IDEA OSG 1 is scheduled for launch in 2018, and will contribute to refining current debris distribution models and improving the ability of spacecrafts in assessing the collision risk in the high-risk orbits. 4)

OSG – the main supporter of the mission, is actively contributing to global manufacturing industries including aerospace, automotive, die/mold, and many others. In support of Astroscale and its promotion of the IDEA OSG 1 mission, OSG hopes to further encourage space development as well as relating manufacturing industries.

Background

Sub-millimeter size debris data were originally gathered by scanning the surfaces of returned spacecraft such as NASA's LDEF (Long Duration Exposure Facility) and Space Shuttles. After the end of the Shuttle program, there has been limited availability to measure the sub-millimeter size debris environment by means of returned materials via ISS cargo. The data from returned objects is accumulated during the whole mission, and thus the accuracy of the time and location of the collected data is low. Continuous sampling is paramount to understanding the dynamic evolution of the LEO environment. Microsatellites are advantageous in this scenario as they can access space frequently and at low cost by utilizing piggyback launch opportunities. The combination of a microsatellite bus carrying an impact sensor has the potential to be a cost efficient way to maintain a sub-millimeter sampling scheme and to have accurate spatiotemporal data.

The IDEA project, initiated at Kyushu University, aims at developing in-situ debris environmental awareness by constructing a constellation of microsatellites carrying impact detectors developed by JAXA. Based on the mission concept of Kyushu University , IDEA OSG 1, the first of the IDEA series, is developed by Astroscale with the sponsorship of OSG Corporation. IDEA OSG 1 is a 20 kg-class microsatellite with an outer dimension of 400 mm x 400 mm x 600 mm. Launch of IDEA OSG 1 is scheduled in early 2018 as a piggyback launch. IDEA OSG 1 will be put on an elliptic polar orbit with an apogee altitude of 800 km and perigee altitude of 600 km at launch. IDEA OSG 1 will sample the sub-millimeter size debris environment for 2 years after launch.

Mission Architecture

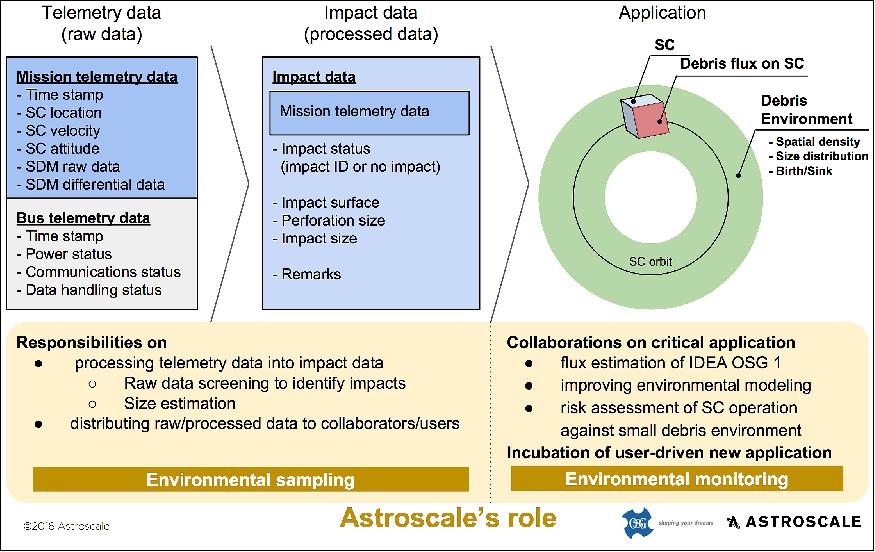

The mission concept is to sample the sub-millimeter size debris environment in space and to analyze the sampled data on the ground in near real-time. To this end, IDEA OSG 1 records the mission telemetry data to on-board non-volatile memory at a regular time period, T, and downlinks them to Astroscale's MCC (Mission Control Center) daily. IDEA OSG 1 has 1 downlink channel in S-band, whose downlink speed is up to 64 kbit/s.

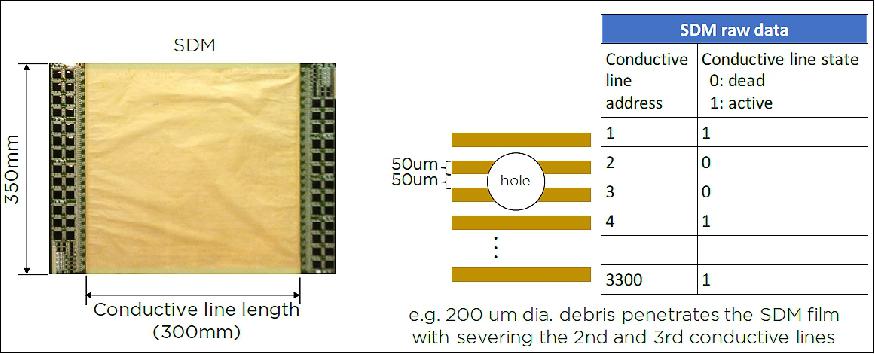

The mission scheme is depicted in Figure 1. One set of the mission telemetry data consists of a GPS time stamp, spacecraft (SC) location, SC velocity, SC attitude, SDM (Space Debris Monitor) raw data from SDM-1 and 2, and SDM differential data. The SDM raw data is the conductive line status of one SDM unit, which is expressed as a 0 or 1 (1 bit) for each conductive line in dead (= severed) or active state, respectively. Since one SDM unit has 3,300 conductive lines, the SDM raw data for one unit is comprised of 3,300 bits. The SDM differential data (Mk ) is the number of severed conductive lines of the two SDMs measured at time tk since the last sampling at tk-1. The calculation of the SDM differential data Mk is done by the SC's onboard computer in real-time by taking the XOR of the raw SDM data at tk and tk-1, and counting the number of true bits. Thus, the SDM differential data instantly indicates whether or not new impacts had occurred during this time frame.

At every downlink operation, a time series of the mission telemetry data except for the SDM raw data are downlinked first to the MCC. If Mk≥1 is detected at time tk, the SDM raw data at tk-1 and tk are downlinked to the ground immediately thereafter. By analyzing the SDM raw data according to a screening guideline at MCC, the impacted SDM and the one-dimensional size of the impact hole are identified as the impact data. This data is also registered to the MCC database as a subset of the mission telemetry data at tk.

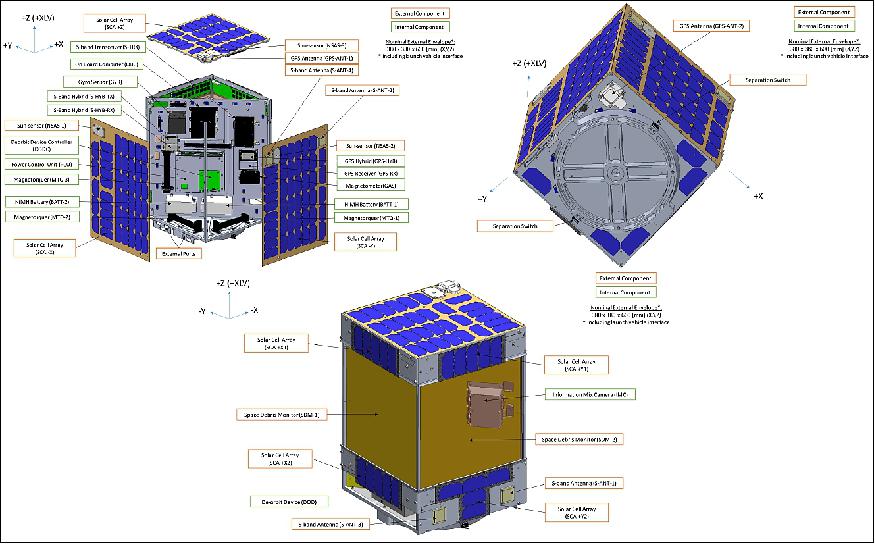

Spacecraft

Figure 2 shows the hardware components of IDEA OSG 1, whose designed hardware lifetime is two years. The structure consists of the SDMs installed on two adjacent sides (defined as the +X and +Y sides) of the spacecraft. The internal space is divided diagonally into two so as to separate the pair of sides with and without the SDMs, with bus hardware installed in the space opposite the SDM. In the space on the same side as the SDM, the IMC (Information Mix Camera) is installed. The satellite bus consists of the following elements:

• RF communications: S-band transceiver

• Power Supply: PCU ( Power Control Unit), 30 W GaAs SCA (Solar Cell Arrays), 10 Ah rechargeable (NiMH) batteries (BATT)

• C&DH (Command and Data Handling): SH4 bus OBC (On-Board Controller), FPGA mission OBC, PIC (Peripheral Interface Controller) watch dog

• ADCS (Attitude Determination and Control Subsystem): Sun sensors (NSAS), magnetometer (GAS), MEMS control gyro (GYR), magnetorquers (MTQ) for 3-axis control

• Timing and Orbit Determination: GPS antennas and receiver (GPS)

• DOD (DeOrbiting Device): A lightweight deployable /retractable sail.

DOD (DeOrbiting Device) Updates

There are two system-level safety requirements regarding the operations of the IDEA OSG 1 spacecraft:

1) If there is sufficient probability that IDEA OSG 1, during its operations, will collide with an uncontrollable resident space object, then IDEA OSG 1 should control its own orbit to the best of its ability to avoid the collision. IDEA OSG 1 shall conduct an operational demonstration of this feature.

2) IDEA OSG 1 should, after termination of its mission, attempt to deorbit in order to meet the 25 year debris mitigation guideline. The deorbit sequence should be "active," meaning that a deorbiting device shall be deployed to reduce the orbital lifetime. IDEA OSG 1 shall conduct an operational demonstration of this feature.

As such, two operational scenarios are considered for the DOD:

a) Collision avoidance by temporarily changing the deployment state of the DOD

b) Orbital lifetime reduction by maintaining the DOD in its deployed state.

In particular, after the end of the extended operations phase, the mission enters the deorbit phase, during which Astroscale will conduct tests on the sail deployment / retraction. As a preliminary test, the DOD sail will transition between deployed and retracted on a weekly basis over three weeks. After the second full state change, Astroscale will determine whether to conduct additional tests based on the project's overall status.

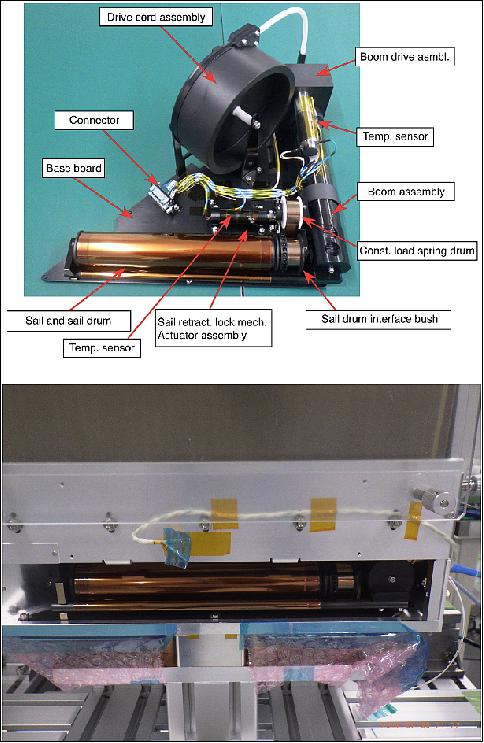

Components

Figure 3 is a picture of the DOD as fabricated on the flight model. The DOD is comprised of the following:

• Sail: Increases the cross-sectional area of the spacecraft. The sail is 3 meters long and 20 cm wide when fully deployed.

• Sail Boom: A multi-segment rod that provides structural rigidity to the Sail.

• Drive Cord: Conveys rotation of the Boom Drive Motor to the Sail Boom when the Sail is deployed / retracted.

• Boom Drive Motor: Deploys and retracts the Sail Boom via the Drive Cord.

• Boom Drive Motor Encoders: Used to estimate the state of the Sail Boom by counting the number of rotations made by the Boom Drive Motor.

• Interlock Motor: Ensures that the sail retraction mechanism does not engage during launch. The lock is disengaged after launch.

• Zero-Point Detection Switch: Detects when the end segment of the Sail Boom is retracted, meaning that the Sail has been fully retracted.

• DOD Controller: The DOD is actuated via the DODC (DOD Controller). The spacecraft's PCU, based on commands from the OBC, controls the DODC. DOD-related commands from the OBC to the PCU are issued from the ground via the OBC.

Launch

The IDEA-OSG 1 microsatellite was launched on 28 Nov. 2017 (05:41 UTC) as a secondary payload on a Soyuz-2-1b/Fregat-M rocket from the Vostochny launch site and experienced a launch failure. The primary payload on this flight was the Russian weather satellite Meteor-M N2-1 of Roscosmos and RosHydroMet (2750 kg). 6) 7)

Orbit: IDEA OSG 1 will be put on an elliptic polar orbit with an apogee altitude of 800 km and perigee altitude of 600 km at launch, inclination =98º.

Secondary Payloads

• Baumanets-2, a remote sensing microsatellite (86 kg) of Bauman University, Moscow.

• LEO Vantage, a communications microsatellite (70 kg) of UTIAS/SFL/Telesat, Canada.

• AISSat-3, a nanosatellite (6.5 kg) of the Norwegian Space Center.

• IDEA OSG-1, an astronomy microsatellite (22 kg) of Astroscale Japan Inc.

• SEAM, an Earth physics nanosatellite (4.7 kg) of the Royal Technology Institute, Sweden.

• Corvus-BC-3 (Landmapper-BC-3, 4), 2 remote sensing nanosatellites (11 kg) of AstroDigital US Inc.

• Lemur-2 x 10, ten navigation nanosatellites (each of 4.5 kg) of Spire Global Inc., San Francisco, CA.

• D-Star One, a communications nanosatellite (3 kg) of German Orbital Systems GmbH.

Sensor Complement

SDM (Space Debris Monitor)

IDEA OSG 1 features a pair of impact sensors called SDM (Space Debris Monitor), developed by JAXA (Japan Aerospace Exploration Agency). 8)

SDM is a simple in-situ sensor designed to detect dust particles ranging from 100 µm to about 1 mm. 3,300 conductive stripes (Ni-Au coated Cu material, 50 µm width) are formed with 100 µm separation on a non-conductive thin film(polyamide material, 12.5 µm thick). A dust particle impact is detected when one or more stripes are severed by the perforation. The length of each conductive stripe is 300 mm; thus, the total detection area of one SDM is 300 mm by 350 mm, or approximately 0.1 m2. The two SDM units are distinguished by name as "SDM-1" and "SDM-2," and are located on the outer body structure of IDEA OSG 1.

IDEA OSG 1 will sample the sub-millimeter size debris environment in one of the most congested regions in LEO by detecting their impacts on the SDM as well as provide key distribution data about their size, time, and location. Data gathered from IDEA OSG 1 are transmitted to a ground-based data processing platform in near real-time. This platform identifies impacts of space debris from the satellite telemetry and transfers the information over the Internet. Data from IDEA OSG 1 will contribute to updating space debris models, provide space debris mapping capabilities, and eventually allow spacecraft manufacturers to use enhanced information for spacecraft shielding designs. 9)

Ground Segment

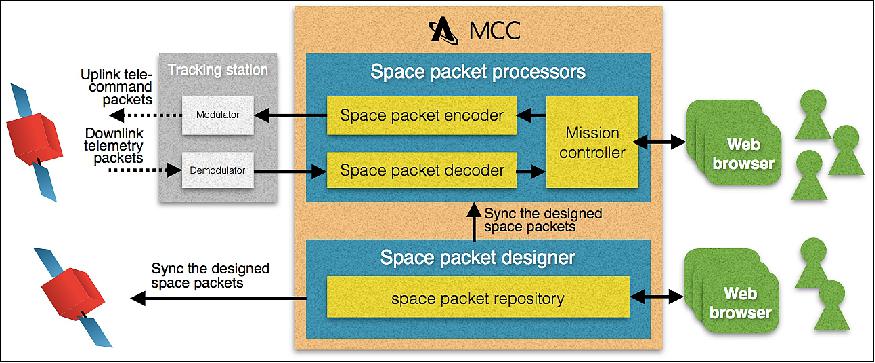

Once IDEA OSG 1 is launched, it will communicate with our GS (Ground Station) via S-band. The MCC (Mission Control Center) is a graphical user interface for all GS operations, including command uplink, telemetry and mission data downlink, and link modulation / demodulation. After the operation engineer sets up commands for the spacecraft, the MCC translates them into standard Space Packet Protocol and interfaces with the GS communication system to establish an uplink. Figure 6 is a block diagram of the IDEA OSG 1 MCC architecture.

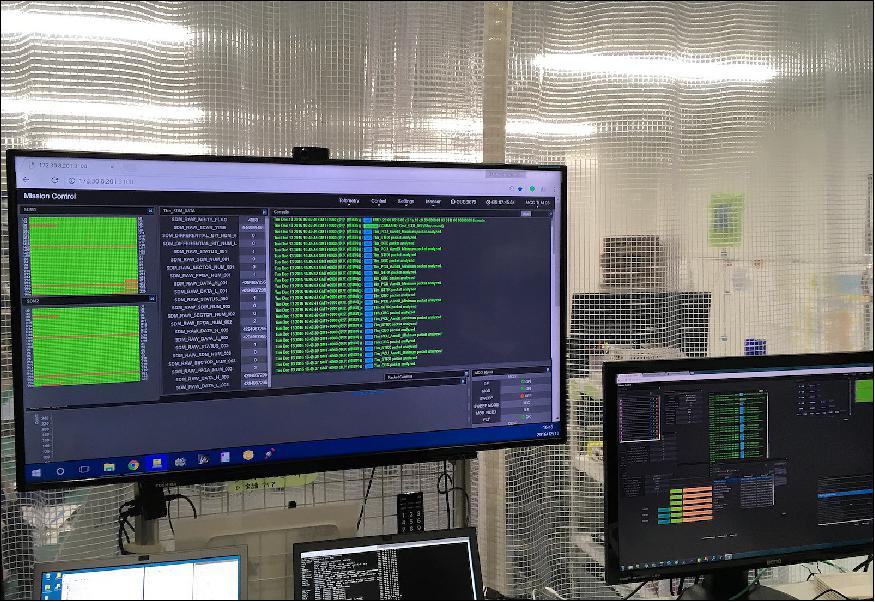

The MCC is currently being tested at our engineering facilities in Tokyo using the IDEA OSG 1 flight model and HILS (Hardware In-the-Loop System). A photograph of the development and testing environment is in Figure 7. Several prominent features include:

• The MCC is programmed entirely in JavaScript and runs on any modern web browser, meaning that it is both scalable and mobile-ready.

• The MCC is capable of both real-time operations as well as scheduled operations based on preset operation scenarios.

• The user can precisely tweak spacecraft commands through the space packet designer module.

• The MCC is designed to take inputs from multiple GS should they be added to the mission.

References

1) Masahiko Uetsuhara, Kohei Fujimoto, Mitsunobu Okada, "IDEA OSG 1: Prelaunch Status Report," Proceedings of the 7th European Conference on Space Debris, ESA/ESOC, Darmstadt/Germany, 18 - 21 April 2017, published by the ESA Space Debris Office, SDC7 paper 710, ADR-2, URL: https://conference.sdo.esoc.esa.int/proceedings/list

2) Note: In December 2015, OSG Corporation of Toyokawa-City, Japan, became a corporate sponsor of Astroscale, a company planning a space debris removal venture. OSG is also supporting the launch of the "IDEA OSG 1" satellite scheduled to take place in 2018.

3) Masahiko Uetsuhara, Mitsunobu Okada, Yasunori Yamazaki, Toshiya Hanada,"Sub-millimeter size debris monitoring system with IDEA OSG 1," Advanced Maui Optical and Space Surveillance Technologies Conference (AMOS), HI, USA, Sept. 19-22, 2016, URL: http://amostech.com/TechnicalPapers/2016/Orbital-Debris/Uetsuhara.pdf

4) "IDEA OSG 1" Project, URL: http://www.ideaosg1.com/en/mission/

5) "ASTROSCALE's Satellite is a Kind of Magnetic Garbage Can," Satnews Daily, July 17, 2017, URL: http://www.satnews.com/story.php?number=1261499852

6) William Graham, "Soyuz 2-1B launch with Meteor-M No 2.1 ends in apparent Fregat-M failure," NASA Spaceflight.com, 27 Nov. 2017, URL: https://www.nasaspaceflight.com/2017/11/soyuz-2-1b-launch-meteor-m/

7) Anatoly Zak,"Soyuz fails to deliver 19 satellites from Vostochny," 11 Dec. 2017, URL: http://www.russianspaceweb.com/meteor-m2-1.html

8) Maki Nakamura, Yukihito Kitazawa, Harihisa Matsumoto, Osamu Okudaira, Toshiya Hanada, Akira Sakurai, Kunihiro Funakoshi, Tetsuo Yasaka, Sunao Hasegawa, Masanori Kobayashi, "Development of in-situ micro-debris measurement system," Advances in Space Research, Volume 56, Issue 3, 1 August 2015, Pages 436-448, https://doi.org/10.1016/j.asr.2015.04.009

9) Koki Fujita, Mitsuhiko Tasaki, Masahiro Furumoto, Toshiya Hanada, "An orbit determination from debris impacts on measurement satellites," Advances in Space Research, Volume 57, Issue 2, 15 January 2016, Pages 620-626, https://doi.org/10.1016/j.asr.2015.11.005

The information compiled and edited in this article was provided by Herbert J. Kramer from his documentation of: "Observation of the Earth and Its Environment: Survey of Missions and Sensors" (Springer Verlag) as well as many other sources after the publication of the 4th edition in 2002. - Comments and corrections to this article are always welcome for further updates (eoportal@symbios.space).

Spacecraft Launch Sensor Complement Ground Segment References Back to top