ISS: NanoRacks Bishop Airlock Module

EO

Operational (nominal)

NanoRacks

Quick facts

Overview

| Mission type | EO |

| Agency | NanoRacks |

| Mission status | Operational (nominal) |

| Launch date | 06 Oct 2020 |

| CEOS EO Handbook | See ISS: NanoRacks Bishop Airlock Module summary |

ISS Utilization: NanoRacks Bishop Airlock Module

Airlock Overview Status Launch References

The deployment of CubeSats and other small satellite payloads from the orbiting laboratory by commercial customers and NASA has increased in recent years. To support demand, NASA has accepted a proposal from NanoRacks to develop the first commercially funded airlock on the space station. 1)

- “We want to utilize the space station to expose the commercial sector to new and novel uses of space, ultimately creating a new economy in low-Earth orbit for scientific research, technology development and human and cargo transportation,” said Sam Scimemi, director, ISS Division at NASA Headquarters in Washington. “We hope this new airlock will allow a diverse community to experiment and develop opportunities in space for the commercial sector.”

- In addition to the large number of CubeSats and small satellites NanoRacks wants to deploy from station, their proposed airlock will also be capable of supporting multiple external payloads.

- Signaling a significant step forward in their airlock plans, NanoRacks announced an independent partnership with Boeing on Feb. 6, 2017, to develop the airlock. Once NanoRacks successfully completes the phases outlined in a Space Act Agreement NanoRacks signed with NASA in 2016, the agency has committed to install the airlock for commercial use, research, and technology demonstrations from the International Space Station. 2) 3) 4)

- In May 2016, NanoRacks and NASA signed a Space Act Agreement in order to install a private airlock module onboard the ISS – the first in station history. The NanoRacks Airlock Module will be both a permanent commercial uncrewed module onboard the International Space Station, and also a module capable of being removed from the space station and used on a future commercial platform.

- NanoRacks has selected Boeing to fabricate and install the Airlock’s PCBM (Passive Common Berthing Mechanism), which is used to connect most pressurized modules of the ISS – and is the most critical piece of hardware for the airlock. The PCBM hardware is being manufactured at the Boeing facilities in Huntsville, Alabama. Boeing will also provide additional engineering services required for developing and manufacturing of the airlock.

- The commercial opportunities through Airlock begin with CubeSat and small satellite deployment from station and include a full range of additional services to meet customer needs from NASA and the growing commercial sector. Currently, CubeSats and small satellites are deployed through the government-operated Japanese JEM/Kibo Airlock. Additionally, the crew on board may now assemble payloads typically flown in soft-stowage ISS Cargo Transfer Bags into larger items that currently cannot be handled by the existing JEM/Kibo Airlock.

- The in-house team at NanoRacks, led by Mr. Brock Howe, will oversee the project management, mechanical and avionics design engineering, safety, operations, quality assurance, mockups and crew training, and the final assembly, integration and testing of the Airlock. Additionally, NanoRacks will be manifesting the Airlock for launch, with an estimated launch in 2020.

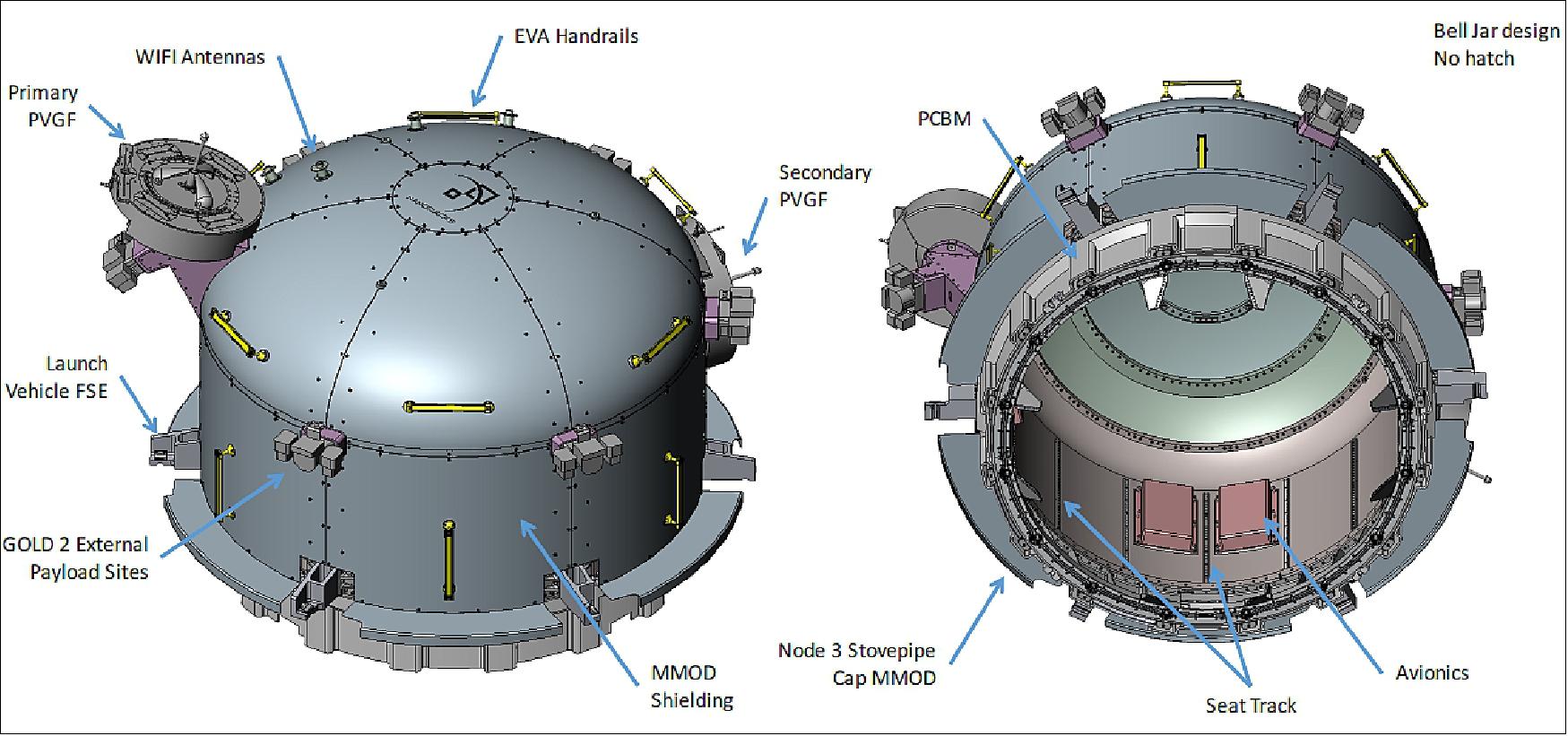

Airlock Overview (Ref. 4)

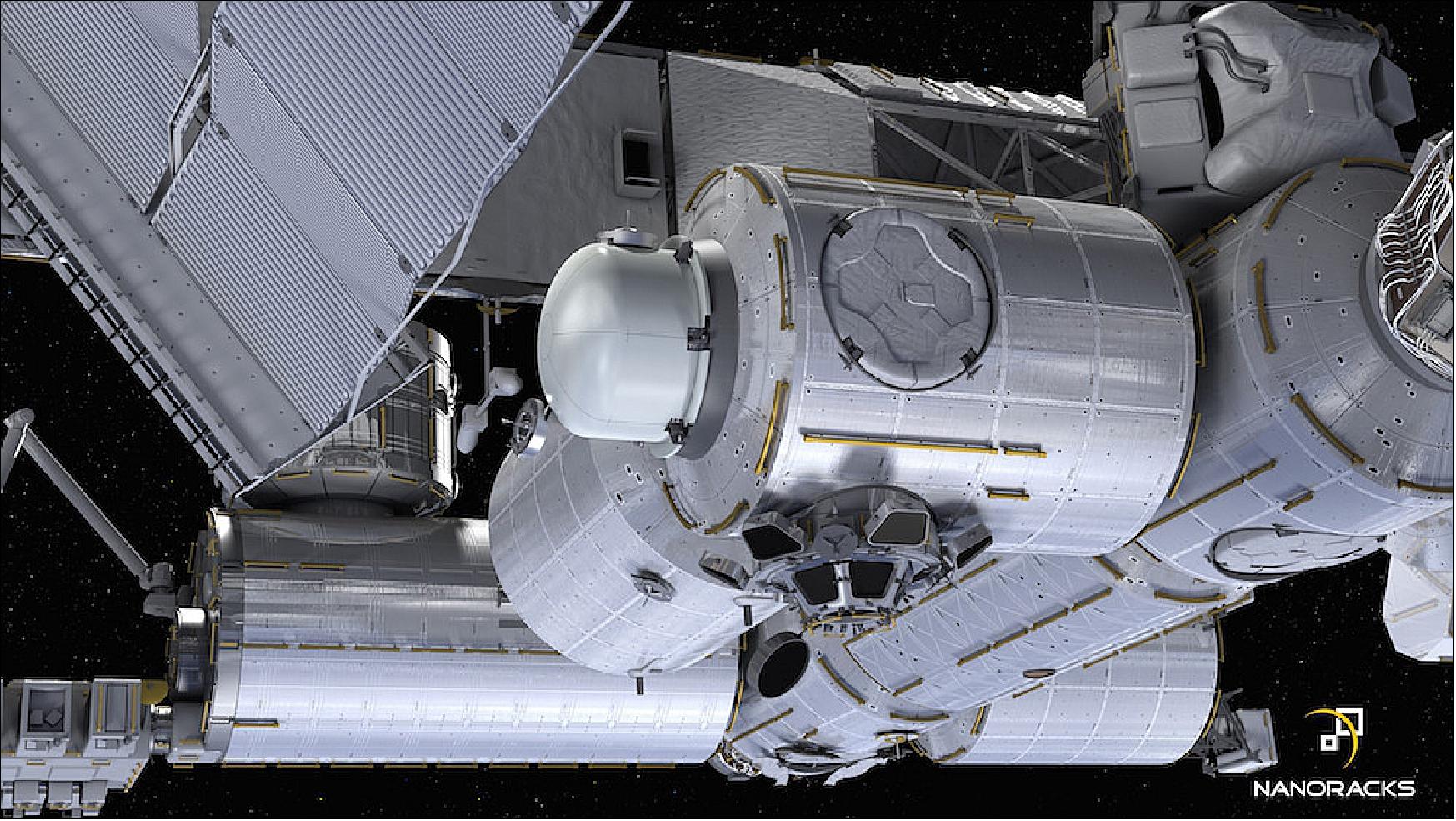

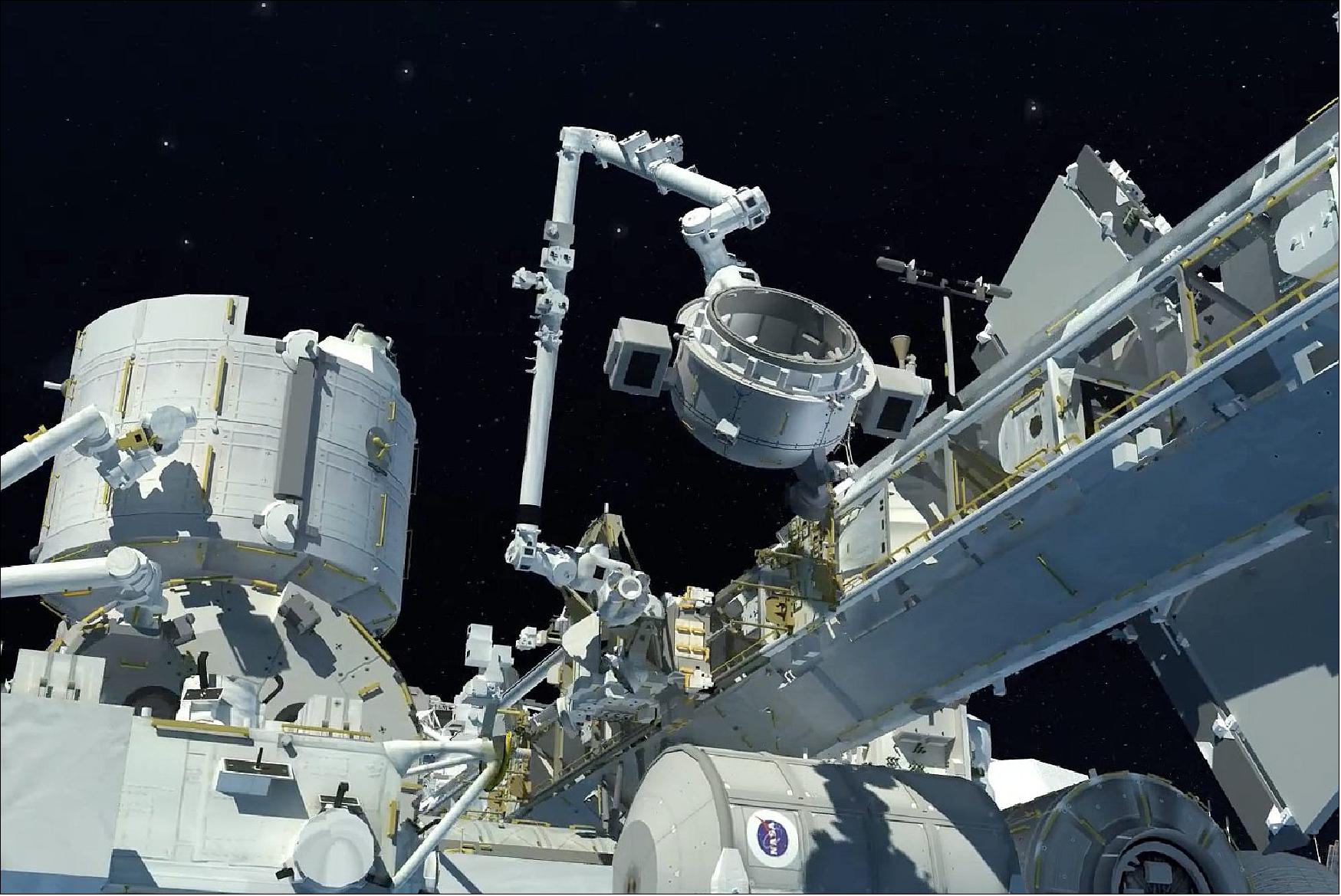

The Airlock is manifested to launch on a Dragon-Falcon 9 flight in 2019. After berthing to ISS, the Airlock will be removed from the Dragon Trunk using the Space Station Remote Manipulator System (SSRMS) and maneuvered and berthed to ISS Node 3, Port Common Berthing Mechanism (CBM) berthing location. Figure 1 shows the installed Airlock onto Node 3, Port.

The Airlock consists of the following systems:

- CDHS (Command and Data Handling System)

- EPS (Electrical Power System)

- Structural System

- TCS (Thermal Control System)

- Video System

- Airlock Utilities

- ISS Wireless System

- Payload Support System

The total mass of Airlock is approximately 1,060 kg.

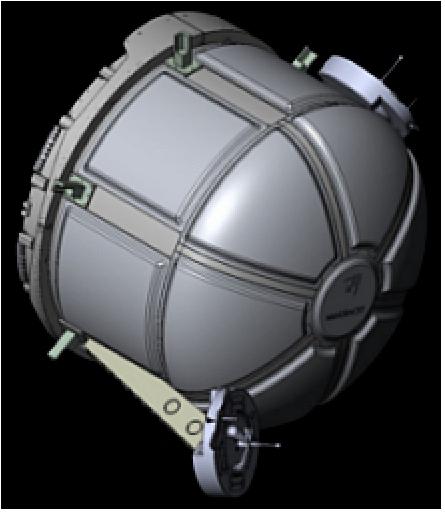

The Airlock structure is a fairly simple structure based on bell jar type pressure shell design. No hatch is included within the Airlock and thus the Node 3 hatch will provide the isolation of the Airlock from the rest of the ISS. A PCBM (Passive Common Berthing Mechanism) will provide the structural interface to the ISS Node 3. Two PVGFs (Power and Video Grapple Fixtures) will provide the interface to the ISS robotics. The Airlock structure also consists of the inner pressure shell with an outer skin that provide MMOD (MicroMeteoroid Orbital Debris) protection.

NanoRacks selected Boeing to fabricate and install the Airlock’s PCBM (Passive Common Berthing Mechanism). PCBM’s are used to connect most pressurized modules of the ISS, and in the case of the Airlock, the PCBM is the most critical piece of hardware. The PCBM hardware is being manufactured at the Boeing facilities in Huntsville, Alabama. Boeing will also provide additional engineering services required for the developing and manufacturing of the Airlock.

Commercial Opportunities

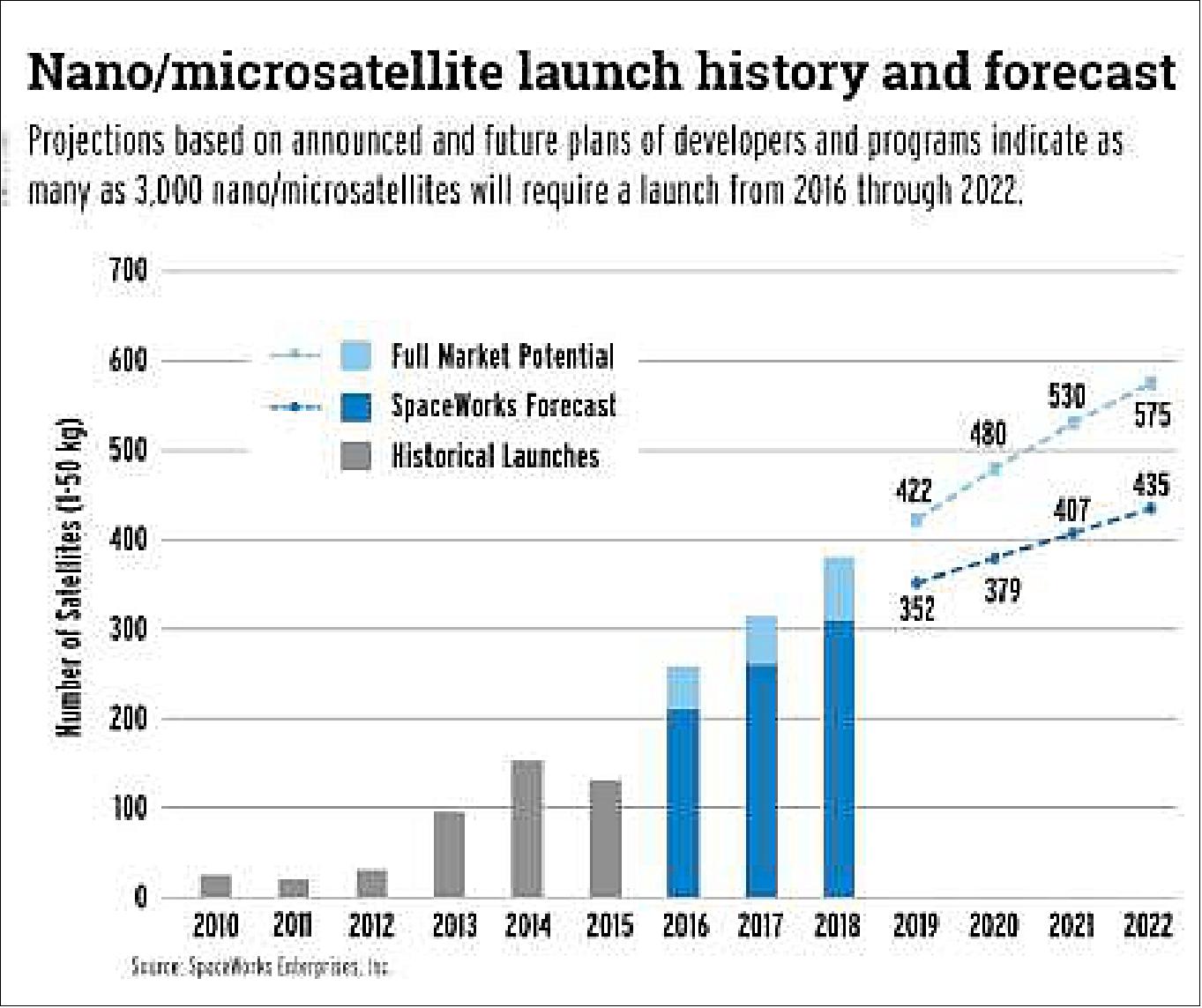

The NanoRacks Airlock Module came to exist as a result of customer demand, a growing market, and, specifically, the need for satellite deployments to operate at a rate demanded by the commercial market. In four years’ time, NanoRacks has deployed nearly 200 CubeSats from the ISS, from universities, companies and governments, with over 50 in the immediate pipeline. Additionally, NanoRacks is preparing to deploy larger satellites, known as “microsatellites,” which are comparable to the size of microwaves. NanoRacks refers to this satellite deployer as the “Kaber” deployer. The first two Kaber satellites were deployed in Fall 2017 (see ISS-Kaber on the eoPortal). - This class of satellites is the fastest growing segment of the market.

• October 24, 2017: Early this morning, NanoRacks successfully deployed the Kestrel Eye IIM (KE2M) microsatellite via the Company's Kaber Microsatellite Deployer (Kaber) from the International Space Station. This is the largest satellite that NanoRacks has deployed to date, and the first deployed from the Kaber deployer. 5)

• On October 27, 2017, NanoRacks successfully deployed NovaWurks’ SIMPL satellite via the Company’s Kaber Microsatellite Deployer (KABER) from the ISS (International Space Station) early this morning. This is the second Kaber-class deployment that NanoRacks completed this week. 6)

NanoRacks continues to prove the International Space Station as an ideal satellite deployment platform for a number of customer needs – including the availability of numerous launch opportunities, ideal deployment inclination for Earth observation, and hands-on operations via the NanoRacks BRIDGE (Base for Research, Investigation, and Deployment ofMicrogravity Experiments) and the astronaut crew on board, including unique photo opportunities of deployments. Additionally, NanoRacks has developed the “Stash and Deploy” concept, in which satellites are stored on the International Space Station for extended periods of time, and deployed on demand when time is critical, rather than waiting for a launch opportunity.

Commercial opportunities through Airlock begin with CubeSat and small satellite deployment from the ISS, and include a full range of additional services to meet customer needs from NASA and the growing commercial sector. Currently, NanoRacks’ customers CubeSats and small satellites are deployed via the NRCSD (NanoRacks CubeSat Deployer) through the Japanese Kibo Airlock. The NanoRacks Airlock Module will offer about five times the payload volume currently accessible via Kibo.

The market demand can be broken down as follows:

1) Government organizations (both U.S. and foreign)

2) Satellites companies

3) Commercial ISS users

4) Educational users.

Role of U.S. Government and Future Implications

NanoRacks has chosen a business model that is quite normal on the Earth, but far less common in the nation’s space program. Fundamentally, NanoRacks pays for its own hardware. For example, NanoRacks has invested $5 million in the Company’s External Platform, over $4 million in the satellite deployment program, close to $1 million in internal research frames., and $15 million to manufacture the Airlock. This expenditure has made the International Space Station more robust, asserted American leadership, and spurred the growth of new markets.

NanoRacks does not seek upfront NASA money because that’s not how the commercial marketplace operates. NanoRacks is focused on the seamless transition from ISS to a marketing place in LEO (Low Earth Orbit) with multiple commercial space stations. The agility of the private sector is needed to create this transition, and eliminate any gaps in LEO presence.

NanoRacks investments, especially in the Airlock, are intended to develop the technical expertise and hardware base to eventually own and operate the Company’s own space stations – a realistic goal the Company has set as United States policy and PPPs (Public Private Partnerships) with NASA have matured.

The Airlock is a pioneer program in the commercial space market. Together with NASA, NanoRacks is forging an even larger partnership than just that for satellite deployment – one where the commercial sector provides hardware, destinations, and resources, and the government acts as a customer. NanoRacks has made it clear to the Space Station Program Office that the Company expects others to enter into partnerships as such with NASA – both for space station use, and for better use of taxpayer resources to further NASA’s mission to bring humans into deep space.

In summary, the NanoRacks Airlock Module, launching in 2019, will dramatically increase commercial activity on the International Space Station, including five times the payload volume for satellite deployment. Boeing is manufacturing the PCBM (Passive Common Berthing Mechanism), the most critical piece of the Airlock. The Airlock will be owned and operated by NanoRacks for the remaining lifetime of the ISS, with Boeing as a partner for the duration, and is capable of being relocated to a future commercial LEO space station.

Development Status

• November 16, 2020: Anyone who has gotten a sofa stuck in a doorway on moving day knows how frustrating it is when there’s no other way in or out. The doorways on the International Space Station, or airlocks, have worked just fine for 20 years. But as more researchers and companies wish to expand the scope and size of the projects they send into low-Earth orbit, a larger doorway could help. 7)

- Opening another portal to receive more shipments and deploy more satellites and experiments is the challenge a private company took up – Nanoracks LLC, headquartered in Webster, Texas. With support from NASA, the company built a new and different kind of doorway into space.

- The Nanoracks Bishop Airlock Module will serve as another door to space, helping to move larger payloads inside and outside the station. This will alleviate one bottleneck slowing down the deployment of new small satellites and CubeSats from the space station. Bishop will also significantly increase the amount of research that can be done in low-Earth orbit – research that helps us better understand the space environment but also has implications for Earth imaging, medical research, and biomanufacturing.

- The new airlock arrives aboard the SpaceX Dragon on the company’s 21st commercial resupply services mission for NASA (CRS-21). It’s the first commercial airlock added to the space station and will be attached to the port on U.S. Node 3, also called Tranquility.

- The arrangement is part of NASA’s strategy to provide more opportunities for U.S. industry with a goal to achieve a sustainable economy in low-Earth orbit from which NASA can be one of many customers. That allows NASA to focus government resources on deep space exploration through the Artemis program and landing the first woman and next man on the surface of the Moon.

- In this case, under a Space Act Agreement, Nanoracks provided the initial investment and the physical structure. NASA will provide power and space-to-ground communication, as well as astronauts to handle cargo and run experiments. Once operational, the new door will mean more access for NASA and everyone else – private companies, academic institutions, public agencies, even citizens.

A Public-Private Partnership (PPP)

- After successfully passing systems test and installation, Bishop will provide five times the capacity of the station’s only other operational airlock being used to send things outside the space station, which is provided by the Japan Aerospace Exploration Agency, or JAXA, as part of its participation in and support of the International Space Station.

- “That’s more volume than can be either brought inside or taken outside right now,” said Mike Read, manager of the space station business and economic development office at NASA’s Johnson Space Center in Houston. In his role supporting NASA’s public-private relationships on the station, Read affirmed the agency’s allocation of the port to the new airlock will serve public and private customers alike.

- The bell jar-shaped airlock also contains multiple rows of standardized tracks for mounting automated modules and other components for housing experiments, as well as electrical and data connections to run and monitor them. There are also six external mounting locations and a WiFi antenna to transmit data.

- Bishop is designed to support a variety of configurations that will support any combination of satellites and experiments. Each time it’s opened to space, the airlock can deploy multiple satellites, while passive experiments can run simultaneously. The robotic arm can be used to extract and launch satellites or mount external experiments. It can also move the airlock to a new position. Different sides of the station, for example, experience different exposure to elements like sunlight or atomic oxygen, enabling a wide range of research possibilities. This flexibility makes it possible to alternate between Earth-observation and astronomical study.

- NASA became an early adopter by pre-purchasing multiple uses of the airlock and is starting with a mundane but recurring need – garbage. Currently, after resupply spacecraft are unloaded, astronauts pack them full of as much trash as possible. The craft and its contents are then allowed to fall into Earth’s atmosphere, where most of it burns up. But the new door could provide an additional alternative to remove large items. “We're going to do some technology demonstrations with trash disposal” to see how it works, Read explained.

- A spacewalk problem could also be solved by outfitting the airlock with a high-tech toolbox. Right now, astronauts need to carry with them all the tools they might need during any extravehicular activity (EVA) as they exit the station. If a different tool is required, they must go back inside – an arduous and time-consuming process. Instead, astronauts could pre-load additional instruments into a toolbox that’s mounted externally for the duration of the EVA on the Bishop Airlock, making spacewalks more efficient.

Using Microgravity

- NASA isn’t the only entity that will benefit from the new airlock. The CubeSat industry is rapidly expanding, from the number of units being deployed to what the little satellites can do. Currently, that expansion is limited by the availability of the single JAXA airlock used for deployments. It quickly became clear that as more companies joined the space economy, “there was going to be congestion” that would lead to launch delays, said Mike Lewis, chief innovation officer with Nanoracks.

- With the new door, Nanoracks aims to keep the pipeline flowing, even as volume ramps up.

- One major application for the CubeSats that have been launched from the space station over the past decade is Earth imaging. This is already used to help farmers monitor fields for better crop management, improve weather forecasts, and more. The new airlock will facilitate additional deployments that could enable higher-resolution images and expanded opportunities for Earth observation.

- The airlock will also increase space for experimental testing in microgravity, which offers advantages for work such as growing living tissues, a long-term goal of the scientific community. This is what's known as biomanufacturing. Previous medical research in microgravity has resulted in improved osteoporosis treatment to help both astronauts and people on Earth mitigate bone loss.

- Nanoracks already has an agreement with NASA and ESA (European Space Agency), which will use the Bishop Airlock to move cargo. Private customers include Gitai, a robotics company that will use the airlock to test robot systems designed to perform work inside and outside the space station.

- Customers expressing interest in using the airlock include commercial space companies, consumer goods manufacturers, and educational organizations. Some have products, services, or research that have already benefited from access to the National Lab and the scientific equipment the company already has onboard – three NanoLab research platforms, a microscope, a centrifuge, and two plate readers, in addition to an exterior-mounted testing platform.

- The increased capacity of the airlock will accommodate more research and other projects on station. Nanoracks’ existing customer base includes Adidas, Aerospace Corporation, Felix and Paul Studios, Millennium Space Systems, MIT Media Lab, the Student Spaceflight Experiments Program, and international space agencies.

- “We’re embarking on more and more public-private partnerships with NASA, building up the ecosystem in low-Earth orbit,” said Nanoracks CEO Jeffrey Manber. “Not only is that important for research opportunities, but it also paves the way for innovations.”

- NASA has a long history of transferring technology to the private sector. The agency’s Spinoff publication profiles NASA technologies that have transformed into commercial products and services, demonstrating the broader benefits of America’s investment in its space program. Spinoff is a publication of the Technology Transfer program in NASA’s Space Technology Mission Directorate.

• October 20, 2020: NanoRacks is pleased to announce that both NASA and the European Space Agency (ESA) have pre-purchased Bishop Airlock Cycles for agency and third-party use. The NanoRacks Bishop Airlock, launching this Fall to the International Space Station (ISS), is the first-ever commercially built, owned, and operated airlock on the ISS and provides five times the existing payload volume currently available on station. 8)

- ESA has pre-purchased five airlock cycles, and NASA six, with an option for four additional cycles at a discounted rate.

- “The signature of this contract is a concrete sign of the European stake in the expanding low-Earth orbit economy,” says Sylvie Espinasse, Head of the European Space Agency’s Washington DC office. “Following ESA member States’ investment in International Space Station research and development, European industry is now stepping in and forging innovative ties with US companies, which bodes very well for the future!” — But the future potential is limitless.

- “Everything that commercial players are doing to show new people that they can actually use microgravity to their benefit is incredibly important,” said Read, adding that the business these companies do will eventually alleviate taxpayers of some of the cost of maintaining the station.

- “We’re thrilled to see both NASA and ESA leveraging commercially available opportunities on the Space Station,” says NanoRacks CEO Jeffrey Manber. “This is how public-private partnerships are supposed to work. Through our Space Act Agreement with NASA, we have been provided access to Node 3 where the Bishop Airlock will live. We then privately funded the Bishop Airlock, using no taxpayer funds for the hardware, and are in turn providing a service at a competitive rate to both the US and European governments, allowing the ISS to function at optimal levels of productivity.”

- Some Bishop use-cases include CubeSat and MicroSatellite deployment, hosted payloads, microgravity and robotics experiments, Extra-Vehicular Activity (EVA) support, and more.

- NanoRacks is continuing to expand use-case opportunities to the US government and is in discussions with NASA on multiple utilization efforts. The Bishop Airlock is allowing NASA to follow the agency goal of serving as one of many customers for commercial services in space, allowing the low-Earth orbit market to expand from beyond just government-provided products and services.

- “We designed Bishop with the future in mind. We knew at the beginning that the first ideas of how to leverage this platform were just that – the first,” says Brock Howe, Bishop Airlock program manager. “But as Bishop has come to life, the ways researchers and engineers are looking at this platform are evolving and we’re excited to build out custom missions for our customers, beyond the scope in which we first imagined Bishop would be used.”

• September 9, 2020: In 2021, space robotics start-up GITAI of Tokyo, Japan, in collaboration with NanoRacks, will conduct a technical demonstration of a GITAI robot executing versatile tasks inside the NanoRacks’ Bishop airlock module installed on Node 3 of the International Space Station (ISS). In this technical demonstration, GITAI’s space robot “S1” will be installed inside Bishop’s pressurized volume to conduct two experiments: IVA (Intra-Vehicular Activity) tasks such as switch and cable operations, and assembly of structures and panels to demonstrate its capability for ISA (In-Space Assembly). All operations conducted by the S1 GITAI robotic arm will be autonomous, followed by some teleoperations from NanoRacks’ in-house mission control. GITAI is managing the technical development of the S1 space robotic arm. NanoRacks is providing the launch opportunity, managing on-orbit operations, and data downlink. NanoRacks is providing this launch opportunity to the ISS via their Space Act Agreement with NASA. 9)

- Through this technical demonstration, GITAI will acquire the technology, know-how, and experience necessary to develop a robot that can conduct versatile tasks in space. This demonstration will be applied to future development of autonomous robots working in the harsh space environment that can conduct docking, repairs, and maintenance tasks for On-Orbit Servicing (OOS) and conduct various tasks for lunar exploration and lunar base construction.

- “We are very excited to be the world’s first private company to conduct a technical demonstration of a space robot, in collaboration with the world’s leading provider of commercial space services, NanoRacks,” says GITAI’s Founder & CEO, Mr. Sho Nakanose. “In the current space market, there are many players trying to solve the space transportation problem, but very few standing up to the challenge to provide an alternative option for getting work done in space. However, in today’s booming space industry, there is a growing demand for versatile tasks to be conducted in space, but in a more reasonable and non-life-threatening manner. With the success of this technical demonstration, GITAI will be able to provide a significantly cheaper and safer means of conducting various tasks in space, which will bring about a true dawn of the space commercialization age.”

- “We are thrilled to be working with GITAI for the first commercial project scheduled in the Bishop Airlock,” says NanoRacks CEO Jeffrey Manber. “We designed Bishop with the goal of providing increased commercial access to the International Space Station (ISS) and building a platform that allows for complex and customizable projects that were not able to be completed on the ISS before. The Bishop Airlock is a place for creativity, and we cannot wait to see GITAI’s robotics come to life and enable incredible new technology.”

• August 5, 2019: In-space transportation startup Momentus announced an agreement with NanoRacks to send Momentus’ Vigoride small satellite shuttle customers into space through NanoRack’s Bishop Airlock Module. 10)

- “We are looking forward to a long and fruitful partnership with NanoRacks,” Momentus CEO Mikhail Kokorich, said in a statement. “The Momentus service offerings are complementary to that of NanoRacks, allowing their customers to go beyond the station to a higher altitude, prolonging their mission life.”

- NanoRacks, a company founded in 2009 to spur commercial utilization of space, launches cubesats and microsatellites for customers from the International Space Station as well as from Northrop Grumman’s Cygnus spacecraft. To offer space access for larger satellites seeking to fly off the space station, NanoRacks is developing the Bishop Airlock Module, which it plans to send to ISS in 2020.

- Once the Bishop Airlock is in place, Momentus will send its Vigoride customers into orbit through the commercial airlock, Momentus and NanoRacks announced Aug. 5 at the Small Satellite Conference here.

- “This is exactly why NanoRacks chose to invest in the first-ever commercial airlock for the space station,” NanoRacks CEO Jeffrey Manber, said in a statement. “Bishop is here to enable technology development and to further enhance our customers’ abilities in space. Momentus is doing both.”

- Momentus plans to conduct a test launch in 2020 of Vigoride, a shuttle to ferry payloads from one location in low Earth orbit to another, by sending a satellite into orbit through NanoRacks’ Kaber Microsat Deployer on the space station. Kaber sends satellites weighing about 82 kilograms or less out of the Japanese Experimental Module airlock.

- Momentus plans to conduct a test launch in 2020 of Vigoride, a shuttle to ferry payloads from one location in low Earth orbit to another, by sending a satellite into orbit through NanoRacks’ Kaber Microsat Deployer on the space station. Kaber sends satellites weighing about 82 kilograms or less out of the Japanese Experimental Module airlock.

- NanoRacks and its partners are designing the Bishop airlock to work both on the International Space Station and on future commercial space stations. Bishop will have five times the volume of the Japanese airlock in addition to platforms for hosted payloads and pressurized research racks, according to the Aug. 5 news release.

- NanoRacks plans to send the Bishop airlock to the space station in 2020 on SpaceX CRS-21 (Commercial Resupply Service-21) mission.

• March 20, 2019: Thales Alenia Space (TAS) is pleased to announce that the shell for Bishop airlock module is ready for ship to the NanoRacks integration facility in Houston, Texas. 11)

- The NanoRacks airlock module - dubbed "Bishop" - is the first-ever commercial airlock that will operate on the International Space Station. Owned and operated by NanoRacks, Bishop will be a permanent commercial module on the ISS. It can also be removed from the ISS for use on future commercial platforms under the NanoRacks Space Outpost Program. Bishop will offer five times more satellite deployment volume than opportunities available on the ISS today. It is scheduled to launch on the SpaceX CRS-21 service mission in January 2020.

- Thales Alenia Space produced and tested the critical pressure shell for Bishop, as well as various secondary structures, including the Micrometeoroid and Orbital Debris (MMOD) shields with multilayer insulation (MLI) panels, the power and video grapple fixture support structure and other structural components.

- NanoRacks is responsible for project management, mechanical and avionics design engineering, safety, operations, quality assurance, mockups and crew training, as well as the final assembly, integration and testing of the Bishop airlock.

• April 17, 2018: The NanoRacks Space Station Airlock Module “Bishop” met another major milestone with completion of the CDR (Critical Design Review) on March 20 and 21, 2018 in Houston, Texas. This milestone begins the transition from the engineering design phase to the fabrication phase. Detailed design drawings such as those for the critical pressure shell will be signed and released to NanoRacks fabrication partner, Thales Alenia Space, in order for them to continue their fabrication efforts. 12)

- Bishop will offer five times the satellite deployment volume than current opportunities available on the Space Station today. The Airlock is manifested to launch in late 2019. 13) 14)

• NanoRacks reports in February 2018, that Thales Alenia Space has been chosen as the latest partner in its commercial airlock program. Thales Alenia Space will produce and test the critical pressure shell for NanoRacks' Airlock Module, which is targeting to be launched to the International Space Station late 2019, and will be used to deploy commercial and government payloads. Thales Alenia Space will also manufacture various secondary structures, including the MMOD (Micrometeoroid Orbital Debris) shields with MLI (Multi-Layer Isolation) panels, the power and video grapple fixture support structure and other structural components. 16)

- "We are very proud of our selection by NanoRacks for this key commercial program," said Walter Cugno, Vice President, Exploration and Science at Thales Alenia Space. "Signing this contract not only ensures our continued role as a global leader in space infrastructures, it also emphasizes our distinctive skills and expertise. Thales Alenia Space will bring to this program over 40 years of experience in the design and production of high-technology solutions and will continue to provide these capabilities both for the International Space Station and for future space exploration initiatives."

- NanoRacks signed a Space Act Agreement with NASA in 2016 to install the first-ever private Airlock Module on the International Space Station. In February 2017, NanoRacks announced a partnership with Boeing to build and install the PCBM (Passive Common Berthing Mechanism), which will connect the Airlock to the rest of the Space Station.

- "Thales Alenia Space was the obvious choice when it came to fabricating our Airlock's pressure shell," said Brock Howe, NanoRacks' Head of Airlock. "Thales Alenia has manufactured over half of the Space Station's pressurized volume, they understand the Space Station's systems and they have produced some of the world's best aerospace hardware. We're looking forward to a very successful partnership that expands our manufacturing alliances into the heart of Europe."

- Thales Alenia Space will produce and test the pressure shell this year, then ship it to NanoRacks' Integration Facility in Houston, Texas in 2019. NanoRacks will integrate the avionics and wiring to complete the airlock assembly.

- NanoRacks' engineering and operations teams will handle airlock integration, functional testing, crew training and final inspections. The Airlock will be then shipped to Florida for final pre-launch preparations and installation on the SpaceX Dragon Trunk, to get ready for the scheduled launch on the SpaceX CRS-19 mission. NanoRacks also teams up with ATA Engineering and Oceaneering on the airlock's subsystems.

• October 3, 2017: NanoRacks announced Oct. 3 that it had raised an undisclosed amount to support development of a commercial airlock module for the International Space Station. 17)

- NanoRacks said that Space Angels led the bridge round investment in the Houston-based company. Formerly known as Space Angels Network, Space Angels provides early-stage funding to companies through its members, individual accredited investors.

- The undisclosed funds will be used for completing a commercial airlock module that NanoRacks plans to install on the ISS in 2019. “This investment will expedite our production, and it’s wonderful to have Space Angels invested in this landmark program to enable the future of commercial space,” Jeff Manber, chief executive of NanoRacks, said in a statement.

- NanoRacks signed an unfunded Space Act Agreement with NASA in 2016 to develop the airlock, which will handle satellite deployments and other experiments that today use the airlock in the Kibo module. “The reason we want our own airlock is this airlock is going to be five times bigger than the current airlock, and it’s going to be far more commercial,” Manber said in a Sept. 27 presentation at the International Astronautical Congress in Adelaide, Australia. - In addition to satellite deployments and experiments, he said the module will be commercial “real estate” on the station, with the ability to mount payloads on its exterior. “It’s getting us more into the real estate business and space station operations,” he said.

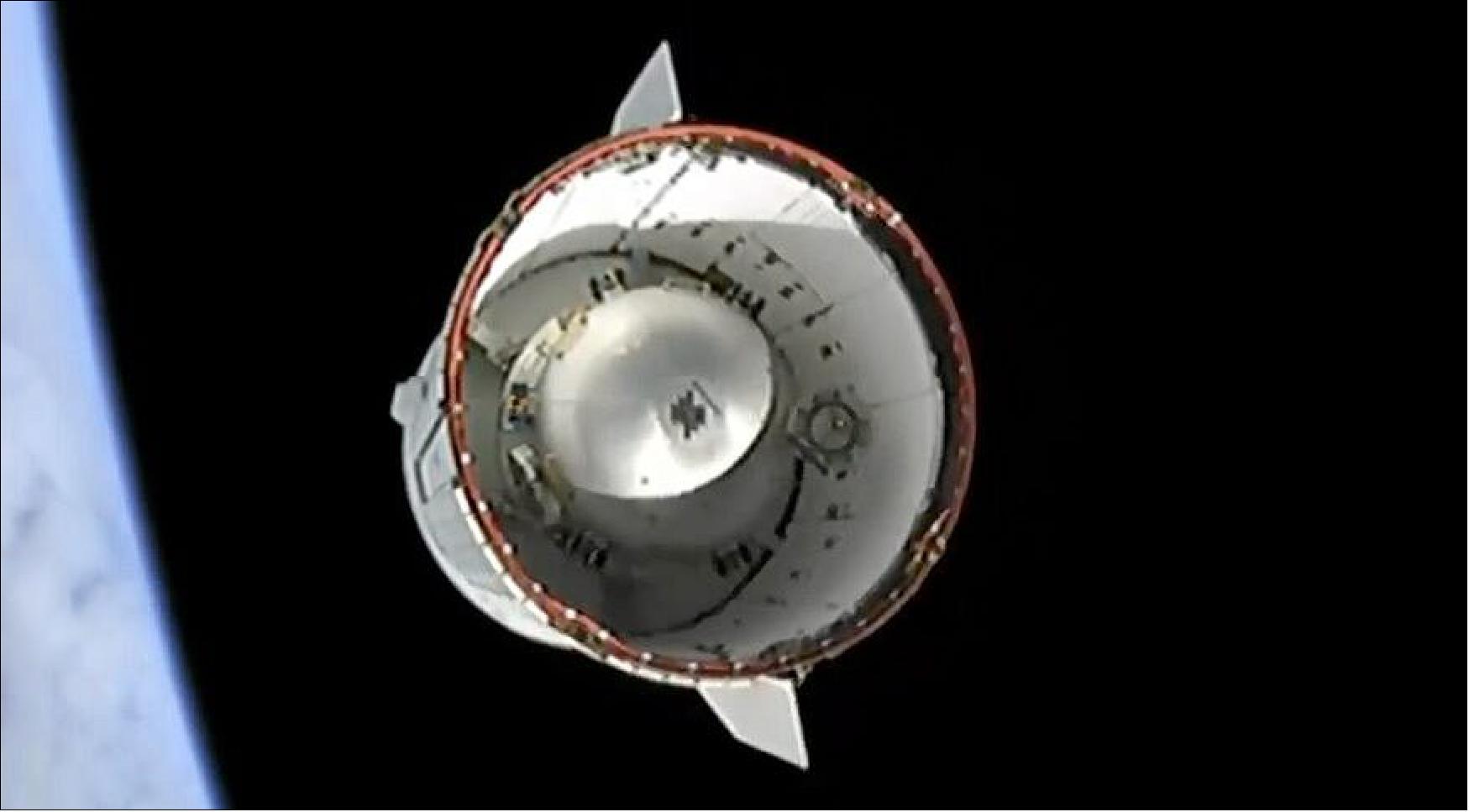

Launch

The NanoRacks Airlock Module Bishop was launched on 6 December 2020 (16:17 UTC) in the upgraded Dragon 2 Trunk of the SpaceX CRS-21 Dragon mission. The launch vehicle was the Falcon-9 v1.2 (Block5) and the launch site was the Cape Canaveral SLC-39A (Space Launch Complex-39A). The mission was contracted by NASA and is flown by SpaceX using a Cargo Dragon. This is the first flight for SpaceX under NASA's CRS Phase 2 contract awarded in January 2016. 18)

The Bishop Airlock is the first permanent, commercial addition to the International Space Station infrastructure. The Bishop Airlock offers 5 x the current volume that can be moved in and out of the Space Station today. Built and operated by NanoRacks, Bishop will enable commercial utilization of the International Space Station to its fullest extent. 19)

SpaceX is set to retire its current fleet of Dragon capsules, in use since 2010, next year and begin flying supplies to the International Space Station on a new variant of the Dragon spacecraft based on the model in development to carry astronauts. After originally awarding SpaceX a cargo transportation contract in 2008 that eventually totaled 20 Dragon missions, NASA selected the company for a follow-on contract — known as Commercial Resupply Services-2 — in 2016 for at least six additional Dragon deliveries through 2024. The changeover to SpaceX’s next-generation Dragon — called Dragon 2 or Crew Dragon — for cargo missions next year will come with several benefits, including a faster process to recover, refurbish and re-fly the capsules. For cargo missions, SpaceX has designed a version of the Crew Dragon, or Dragon 2, spacecraft without SuperDraco abort engines. The launch abort system has been a stumbling block in the Crew Dragon program after a spacecraft exploded during moments before a ground test-firing of the abort engines in April. SpaceX traced the cause of the explosion to a leaky check valve inside the abort engine pressurization system, but investigators cleared the engines themselves from fault. The Dragon 2 spacecraft has a different aerodynamic shape than the first-generation Dragon, which first flew in space in 2010, and reached the space station for the first time in 2012. It can also dock automatically with the space station, without requiring station crews to capture it with the research lab’s Canadian-built robotic arm. The cargo version of Dragon 2 will launch without seats, cockpit controls and other life support systems required to sustain astronauts in space. | |

Since accomplishing the two Dragon test flights, SpaceX has successfully delivered cargo to the space station 17 times. One mission failed during launch on a Falcon 9 rocket in 2015. SpaceX shut down the assembly line for the original Dragon spacecraft design in 2017. The company is flying the remaining cargo missions under the original resupply contract with reused Dragon capsules. SpaceX’s most recent cargo launch, which took off from Cape Canaveral on 25 July 2019, was the first to fly a Dragon spacecraft for a third time. “Dragon 1 is certified for three flights,” said Jessica Jensen, SpaceX’s director of Dragon mission management. “That’s just the maximum we needed with the fleet that already existed.” Two more resupply missions, designed SpaceX CRS-19 and CRS-20, are scheduled for liftoff in December and next March before the new Dragon 2 vehicle begins flying dedicated cargo missions on the SpaceX CRS-21 mission, currently scheduled for launch next August. “Then the Dragon 1 fleet is retired, and we switch over to the CRS-2 contract, where we then fly the Dragon 2 vehicle, which is a modified version of the commercial crew vehicle,” Jensen said in a press conference before last week’s Dragon launch. “That one we are going to certify up front to be qualified for five flights, but we’ll just have to see how the manifest works out. But that’s what we’re aiming for at this point in time.” Jensen said SpaceX tests components on its Dragon cargo vehicles to four times their design lives to certify the spacecraft for three missions. “We have to make sure that all the hardware on it is qualified for three flights, and we do that early on,” Jensen said. “For example, if there’s a bottle on Dragon that’s going to see 10 pressurization cycles each flight, you have to make sure that it can survive 30 pressurization cycles in a row. “And when we do that, we test the bottle not only to 30 pressurization cycles, but we multiply that by a factor of four to get to 120,” she said. “So we do that process basically for every component and every subsystem on dragon. We ensure that it has margin to survive all three flights. That’s the first thing we do.” | |

Beginning with the CRS-21 mission next year, the new Dragon 2 cargo capsules will splash down under parachutes in the Atlantic Ocean east of Florida, rather than the current recovery zone in the Pacific Ocean west of Baja California. “We plan to do all of the refurbishment (on Dragon 2) here in Florida,” Jensen said. “The fact that we don’t have to transport it to Texas, and to Hawthorne, and back to Florida, that’s going to actually save us a lot of time. “We have also designed the vehicle from the onset to be easily inspected and refurbished, so the Dragon 2 turnaround times are going to be much faster,” she said. SpaceX encountered problems with salt water seeping into the Dragon spacecraft during splashdowns earlier in the cargo resupply program. “With vehicles splashing down in the ocean, you want to minimize salt water intrusion as much as possible,” Jensen said. “I think we’ve learned a lot about how to water seal a vehicle. I think that’s been the biggest (lesson) learned. One is water sealing, and then the other one is accessibility, making sure that you can access the areas that will need to be inspected, and you can do that quickly. “We learned all of that on Dragon 1 and then designed Dragon 2 from the onset to have better water sealing and easier for access and refurbishment,” Jensen said. SpaceX does not initially plan to reuse Dragon 2 capsules on missions with astronauts. Jensen said SpaceX does not foresee any delays in readying the Dragon 2 for cargo missions next year, even if modifications and testing of the abort system needed for piloted flights encounter further schedule slips. “The cargo Dragon 2 capsule does not have the SuperDraco high-flow abort system,” she said. “So while it is largely the same vehicle, the system that was involved in our in-flight abort test anomaly is not on the cargo Dragon 2 vehicle. Jensen said SpaceX plans to launch its Dragon 2 cargo missions from pad 39A at the Kennedy Space Center, the same facility that will host crew launches. That will allow ground teams to load last-minute supplies and time-sensitive experiments into the capsule using the access arm built for astronauts. SpaceX currently uses a mobile clean room to install the final cargo into the Dragon spacecraft at nearby pad 40. |

Orbit: Near-circular orbit of the ISS, altitude of ~400 km, inclination = 51.6º, period = 93 minutes.

The largest payload on the spacecraft is the Bishop airlock for Nanoracks. The company built the airlock as a commercial facility for use deploying satellites and hosting external payloads. The station’s robotic arm will remove Bishop from Dragon’s trunk shortly after docking and install it on the Tranquility, or Node 3, module of the station.

“This is a monumental moment for Nanoracks,” Jeff Manber, chief executive of Nanoracks, said in a statement after launch (Ref. 18). “We came up with this idea five years ago. In those five quick years, we’ve gone from being known as the ‘CubeSat’ deployment company to an organization that is building the future of commercial low Earth orbit infrastructure.”

References

1) Mark Garcia, ”Progress Underway for First Commercial Airlock on Space Station,” NASA, Feb. 6, 2017, URL: https://web.archive.org/web/20230811162655/https://www.nasa.gov/feature/progress-underway-for-first-commercial-airlock-on-space-station/

2) ”New airlock is a big step towards transition to more commercial ISS,” NanoRacks, Feb. 6, 2017, URL: http://nanoracks.com/nanoracks-boeing-first-commercial-airlock-module-on-iss/

3) ”NanoRacks, Boeing to Build First Commercial Airlock Module on International Space Station,” NanoRacks Press Release, Feb. 6, 2017, URL: http://nanoracks.com/wp-content/uploads/

NanoRacks-Release-59-NanoRacks-Boeing-First-Commercial-Airlock-Module-on-ISS.pdf

4) Jeffrey Manber, Kevin D. Foley, ”The First Commercial Airlock Module: Building The Commercial Space Market,” Proceedings of the 68th IAC (International Astronautical Congress), Adelaide, Australia, 25-29 Sept. 2017, paper: IAC-17-F1.2.3

5) ”NanoRacks Successfully Deploys First Customer Microsatellite from ISS, Largest to Date,” NanoRacks, 24 Oct. 2017, URL: http://nanoracks.com/largest-customer-microsatellite-deployed/

6) ”NanoRacks Deploys Second Kaber-Class Microsatellite This Week, First On-Orbit Assembly,” NanoRacks, 27 Oct. 2017, URL: http://nanoracks.com/second-kaber-microsatellite-deployed/

7) Margo Pierce, ”A New Doorway to Space,” NASA Spacetech, 16 November 2020, URL: https://www.nasa.gov/directorates/spacetech/spinoff/New_Doorway_to_Space

8) ”Bishop Airlock Cycles Pre-Purchased by NASA and European Space Agency,” NanoRacks Press Release, 20 October 2020, URL: https://nanoracks.com/bishop-airlock-nasa-esa-purchase/

9) ”GITAI & Nanoracks announce technical demonstration of a GITAI robot inside the Nanoracks Bishop Airlock,” NanoRacks Press Release, 9 September 2020, URL: https://nanoracks.com

/gitai-nanoracks-bishop-airlock/

10) Debra Werner, ”Momentus to rely on NanoRacks airlock for Vigoride shuttle,” Space News, 5 August 2019, URL: https://spacenews.com/momentus-nanoracks-pact/

11) ”Thales Alenia Space reaches key milestone for NanoRacks' airlock module,” Thales Group, 20 March 2019, URL: https://www.thalesgroup.com/en/worldwide/space/press-release/

thales-alenia-space-reaches-key-milestone-nanoracks-airlock-module

12) ”NanoRacks Commercial Space Station Airlock "Bishop" Completes Critical Design Review, Moves to Fabrication,” SpaceRef, 17 April 2017, URL: http://spaceref.com/news/viewpr.html?pid=52467

13) ”NanoRacks Airlock Module: Bishop,” NanoRacks, URL: http://nanoracks.com/products/airlock/

14) ”Bishop: The NanoRacks Airlock Module -Your Commercial Gateway to Space,” NanoRacks, URL: http://nanoracks.com/wp-content/uploads/NanoRacks-Airlock-Presentation.pdf

15) Brock Howe, ”NanoRacks Airlock Module - The Commercial Gateway to Space,” NanoRacks, URL: http://nanoracks.com/wp-content/uploads/NanoRacks-Airlock-Presentation.pdf

16) ”NanoRacks adds Thales Alenia Space to team up on Commercial Space Station Airlock Module,” Space Daily, 5 Feb. 2018, URL: http://www.spacedaily.com/reports/NanoRacks_adds_

Thales_Alenia_Space_to_team_up_on_Commercial_Space_Station_Airlock_Module_999.html

17) Jeff Foust, ”NanoRacks raises funding for commercial airlock module,” Space News, 3 Oct. 2017, URL: http://spacenews.com/nanoracks-raises-funding-for-commercial-airlock-module/

18) ”Bishop Airlock Takes Flight,” NanoRacks Press Release, 6 December 2020, URL: https://nanoracks.com/bishop-airlock-takes-flight/

19) ”Bishop Airlock - The commercial Gateway to space,” NanoRacks, URL: https://nanoracks.com

/bishop-airlock/

20) Stephen Clark, ”SpaceX to begin flights under new cargo resupply contract next year,” Spaceflight Now, 2 August 2019, URL: https://spaceflightnow.com/2019/08/02/

spacex-to-begin-flights-under-new-cargo-resupply-contract-next-year/

21) Jeff Foust, ”SpaceX launches first next-generation cargo Dragon spacecraft to ISS,” SpaceNews, 6 December 2020, URL: https://spacenews.com/

spacex-launches-first-next-generation-cargo-dragon-spacecraft-to-iss/

The information compiled and edited in this article was provided by Herbert J. Kramer from his documentation of: ”Observation of the Earth and Its Environment: Survey of Missions and Sensors” (Springer Verlag) as well as many other sources after the publication of the 4th edition in 2002. - Comments and corrections to this article are always welcome for further updates (eoportal@symbios.space).